For mid-market consumer packaged goods ( CPG ) companies, the journey from regional success to national distribution is fraught with operational challenges. As your brand gains traction and retail partnerships expand, the third-party logistics ( 3PL ) providers that served you well in the early days can become the very obstacle preventing your next phase of growth.

Most mid-market CPG operations are flying blind through their most critical scaling phase, unaware of the costly inefficiencies hiding within their 3PL relationships. These blind spots don't just impact your bottom line; they can derail promising brands entirely.

The Mid-Market CPG Dilemma

Mid-market CPG brands occupy a challenging position in the consumer goods landscape. You've moved beyond startup logistics but haven't yet achieved the scale where enterprise-grade supply chain infrastructure makes economic sense.

This creates a perfect storm. Your volumes are too large for manual tracking but too small to command priority attention from major 3PL providers. Your CPG supply chain needs are increasingly complex, yet your margins can't absorb enterprise solution costs.

The consequences are significant. According to McKinsey research , autonomous supply chain planning can increase revenue by up to 4%, reduce inventory by up to 20%, and lower supply chain costs by up to 10%. Yet most mid-market brands lack access to these capabilities. A Kearney study found that about $800 billion will be left on the table by consumer products companies unless they upgrade their supply chain operations.

Blind Spot #1: Inventory Visibility Gaps

The first and most dangerous blind spot in CPG operations is incomplete inventory visibility. When you ask your 3PL for current inventory levels, you're often receiving data that's hours or even days old. In the fast-moving consumer goods sector, that lag can be catastrophic.

Consider this scenario: Your largest retail partner places an urgent replenishment order. Your 3PL dashboard shows adequate inventory. You confirm the order, only to discover three days later that a significant portion was damaged, already allocated, or miscounted.

This isn't hypothetical; it's daily reality for countless mid-market CPG brands. While enterprise clients receive real-time inventory integration and dedicated account managers, mid-market clients typically work with batch updates and shared resources.

The blind spot deepens when you operate with multiple 3PLs across different regions. Each uses different systems, reporting frequencies, and methodologies. Reconciling these disparate data sources becomes a full-time job, yet most brands in this segment lack dedicated supply chain personnel.

Research shows that top-performing 3PLs maintain 99%+ inventory accuracy through real-time tracking, yet many mid-market brands work with providers using outdated, manual methods that aren't scalable long-term.

Blind Spot #2: Hidden Fees and Cost Creep

The second major blind spot involves the true cost of your 3PL relationships. Mid-market CPG operations typically sign contracts based on straightforward per-unit or per-pallet pricing. What they don't anticipate is the extensive menu of additional fees that accumulate over time.

Storage overages. Handling fees for returns. Special processing charges for promotional kitting. Expedite fees. Receiving inspection charges. Pallet transfer fees. The list grows longer each quarter.

The blind spot emerges because most mid-market brands lack systems to track and analyze these charges systematically. Your AP department pays the invoices, but no one aggregates the data to understand patterns or negotiate better terms.

Since 2019 , the cost of wholesale materials for consumer goods businesses has risen by 35%, adding pressure to already tight margins. Consumer goods operations often discover their effective 3PL costs are significantly higher than base contract rates once all fees are included.

The problem intensifies as you grow. Each new SKU adds complexity. Each new retail partner brings unique requirements. Each new region requires additional coordination. As one DTC scaling study noted, every additional SKU comes with hidden costs, approximately $50,000 annually for inventory management, forecasting, and creative updates.

Blind Spot #3: Order Accuracy and Fulfillment Failures

Your 3PL reports a 99.2% order accuracy rate. Impressive, right? But that single metric obscures issues that directly impact your brand reputation and retail relationships.

That 0.8% error rate might represent your most important orders going to your biggest retail partners or time-sensitive promotional launches. 3PL dashboards don't distinguish between a mispick on a small order and a critical shortage on a major distribution center shipment.

Research shows that warehouses often experience a 1-3% error rate during picking, and around 23% of returned orders stem from customers receiving the wrong items. More concerning, industry estimates show that mispicks can cost between $50 and $300 per incident and that approximately 30% of customers will not reorder after receiving the wrong item.

The blind spot extends to understanding why errors occur. Was it a mispick, inventory discrepancy, system glitch, or miscommunication? Without visibility into root causes, you can only react to symptoms.

Consider the cascading effects of fulfillment failures. A shorted order doesn't just mean lost sales for that shipment. It means empty shelf space your competitor fills, strained buyer relationships, and potential lost distribution. Industry data confirms that 1 in 5 customers won't reorder after a single fulfillment error, making accuracy a critical driver of customer lifetime value.

Blind Spot #4: Data Fragmentation Across the Supply Chain

Modern CPG operations generate enormous amounts of data, but the challenge for mid-market brands isn't lack of data; it's data fragmentation.

Your 3PL has one system. Your ERP is another. Your e-commerce platform is a third. Your broker uses yet another. Each generates reports in different formats, with different timing, using different terminology.

This fragmentation creates a blind spot where critical insights should exist. You can't easily answer: What's my true landed cost by SKU? Which retail partners are most profitable? Where are my supply chain bottlenecks? How much working capital is trapped in slow-moving inventory?

Research confirms that fragmented operations create inefficiencies that inflate expenses, as siloed systems, disconnected teams, and redundant processes slow decision-making and add unnecessary complexity.

The data fragmentation problem worsens as you scale. Each new 3PL adds another data silo. Each new retail partner brings different EDI requirements. The complexity grows exponentially while your resources grow linearly at best.

Blind Spot #5: Lack of Proactive Communication and Accountability

Perhaps the most frustrating blind spot is the reactive nature of 3PL communication. Mid-market CPG operations rarely learn about problems before they become crises.

Your 3PL doesn't proactively alert you when inventory is running low until you're completely out. They don't flag quality issues until after distribution. They don't mention capacity constraints until the week you need to store your holiday inventory surge.

This stems from how 3PLs allocate resources. Enterprise clients receive dedicated account managers who provide strategic guidance. Mid-market clients typically work with shared customer service teams focused on addressing immediate issues rather than preventing future ones.

The accountability blind spot becomes apparent when things go wrong. Determining responsibility becomes a finger-pointing exercise. Without clear accountability frameworks and transparent data, resolving disputes and preventing recurrence becomes nearly impossible.

The Scaling Threshold: When Blind Spots Become Critical

These blind spots become particularly dangerous at specific scaling thresholds:

- The Multi-Region Expansion: When you move from one 3PL to multiple regional providers, visibility challenges multiply exponentially.

- The Major Retail Breakthrough: Landing that first big-box retailer transforms operational requirements overnight. Their demands for order accuracy, lead times, and compliance are typically more stringent than anything you've experienced.

- The Product Line Extension: Adding new product categories or significant SKU expansion strains systems built for simpler operations. The manual workarounds that functioned with 20 SKUs collapse under the weight of 100+ SKUs.

- The Rapid Growth Phase: When orders increase 50-100% year-over-year, operational blind spots that were manageable annoyances become existential threats. Research on DTC brands shows that 73% of brands fail when scaling from $10 million to $50 million in revenue, often because operational inefficiencies turn early-stage strategies into liabilities.

The Cost of Blind Spots: Beyond Dollars

The true cost extends beyond finances. Mid-market CPG brands operating with these limitations face:

- Missed Growth Opportunities: Retailers want confidence in your operational capabilities. Brands with fulfillment issues lose opportunities to more operationally mature competitors.

- Strategic Distraction: Leadership teams spend countless hours firefighting operational issues rather than focusing on product innovation, brand building, and market development.

- Cash Flow Constraints: Without accurate visibility and cost tracking, working capital management becomes guesswork. According to research on mid-market businesses , experiencing payment delays threatens to shrink working capital, and as firms grow, they struggle to sustain the same manual processes.

- Team Burnout: Operations personnel work excessive hours managing these blind spots manually, leading to turnover and institutional knowledge loss. Research confirms that nearly 4 out of 10 mid-market executives say their company's ability to grow is constrained by lack of talent.

- Damaged Retail Relationships: In the competitive consumer goods landscape, buyers have abundant alternatives. Brands that consistently struggle with fulfillment gradually lose shelf space and distribution opportunities.

Breaking Through: Eliminating Blind Spots

The good news is that these blind spots aren't inevitable. Mid-market CPG operations can achieve the visibility and control previously available only to enterprise brands.

Unified Data Integration: The foundation is bringing disparate data sources together into a single, real-time view, integrating 3PL systems, ERPs, e-commerce platforms, and retail partner connections into one operational dashboard.

Automated Monitoring and Alerts: Modern CPG supply chain systems should proactively monitor for anomalies and alert you immediately. Low inventory thresholds, quality issues, unusual fee patterns, and order delays should trigger automatic notifications.

Predictive Analytics: Historical data combined with AI-driven insights can forecast inventory needs, identify optimal reorder points, predict potential stockouts , and highlight cost-saving opportunities before they become urgent.

Performance Benchmarking: Understanding whether your 3PL is performing well requires industry benchmarks and comparative analytics. Top-tier 3PLs maintain order accuracy rates above 99.5%.

Accountability Frameworks: Clear data trails and performance metrics create accountability, allowing you to quickly identify root causes and responsible parties.

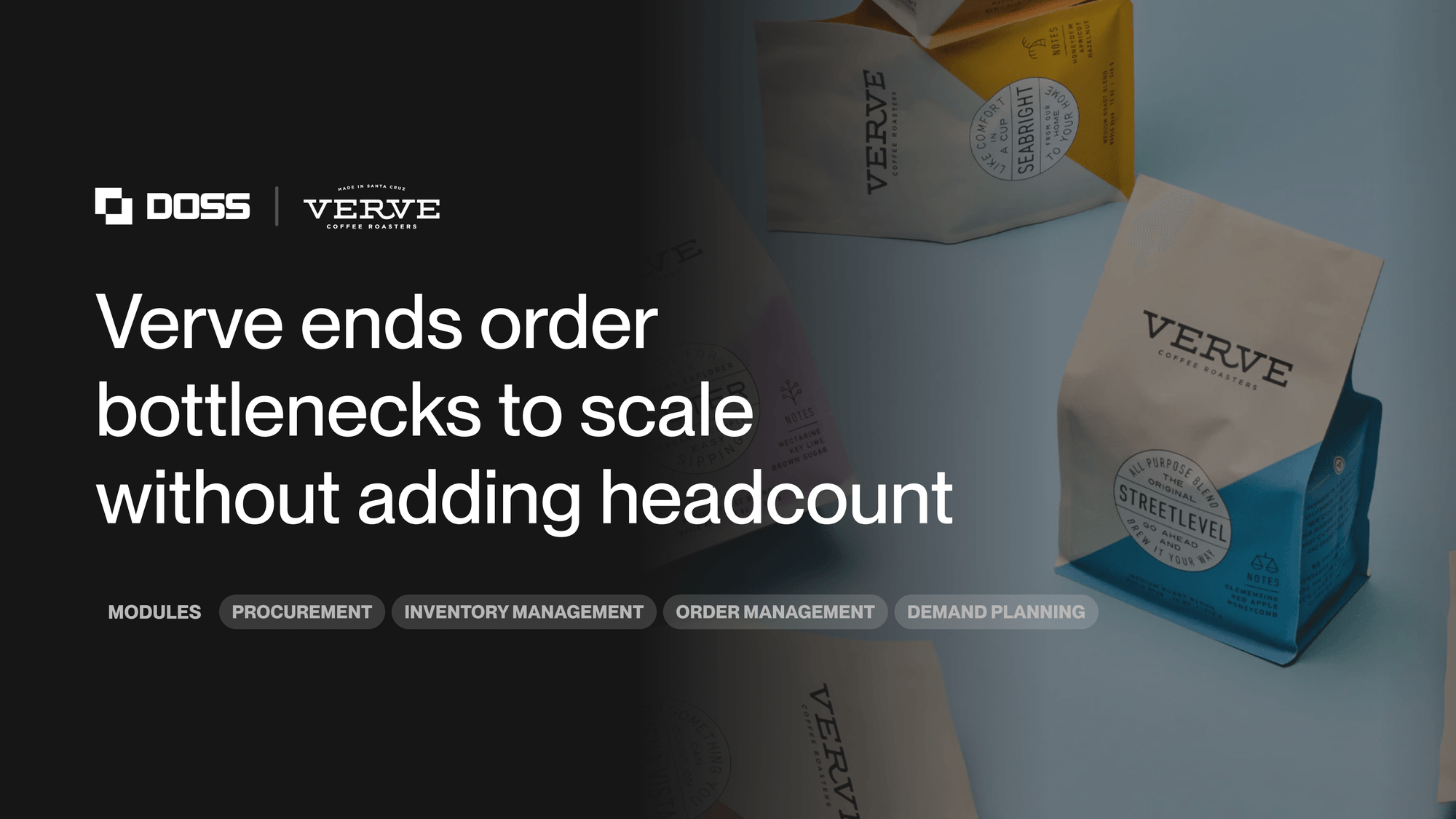

How DOSS Operations Solves Mid-Market CPG Blind Spots

DOSS Operations Cloud was built specifically to address the unique challenges facing mid-market consumer packaged goods companies navigating the scaling phase. Unlike enterprise solutions designed for Fortune 500 supply chains or basic inventory tools built for startups, DOSS provides the precise level of functionality and affordability that mid-market CPG operations need.

Real-Time 3PL Integrations: DOSS connects directly to your 3PL providers, pulling real-time inventory data, order statuses, and fulfillment information into a unified dashboard. Whether you work with one 3PL or multiple regional providers, DOSS gives you a single source of truth for your entire operation.

Intelligent Cost Tracking: Every fee, surcharge, and cost is automatically captured and categorized. DOSS's analytics engine identifies cost creep patterns, flags anomalies, and provides actionable insights for negotiating better 3PL terms.

Proactive Monitoring: DOSS doesn't wait for you to discover problems. The platform continuously monitors your CPG supply chain, alerting you to low inventory, unusual patterns, quality issues, or fulfillment delays before they impact your retail partners.

Purpose-Built for Consumer Products: Unlike generic supply chain software, DOSS understands the nuances of consumer goods operations: lot tracking, shelf life management, promotional kitting, retail compliance requirements, and the complexities of managing multiple SKUs across various channels.

Accessible Pricing: DOSS delivers enterprise-grade visibility and control at a price point that makes sense for mid-market brands, without the six-figure implementations that put traditional solutions out of reach.

Scalable Architecture: As your brand grows, DOSS scales with you. The platform that serves you with $5M in annual revenue continues providing value at $50M, $500M and beyond.

Taking Control of Your CPG Operations

The scaling phase is the most critical period in a mid-market CPG brand's journey. The operational blind spots that develop during this phase determine whether you successfully navigate to the next level or stall out amid preventable crises.

Eliminating these blind spots doesn't require massive capital investment or years-long implementations. It requires acknowledging that the informal processes and manual workarounds that got you here won't get you where you want to go.

The brands that successfully scale from mid-market to market leaders achieve operational excellence before it becomes urgent. They recognize that operational capabilities are a competitive advantage, not just a cost center. They invest in visibility and control during the growth phase, positioning themselves to capitalize on opportunities rather than scramble to meet basic requirements.

Your 3PL blind spots are costing you money, limiting your growth, and putting your brand reputation at risk. The question isn't whether you need better visibility; it's whether you'll address these gaps before they derail your growth trajectory.

DOSS Operations provides mid-market CPG brands with the operational clarity and control needed to scale with confidence. By eliminating the blind spots that plague consumer goods operations, DOSS empowers your team to focus on what matters most: building a brand that captures market share and delivers value to retail partners and consumers alike.

Ready to eliminate your 3PL blind spots and unlock your brand's growth potential? Discover how DOSS Operations can transform your CPG supply chain from a source of constant concern into a competitive advantage.